Quick Facts About Bollard Load Testing

Yes, exactly as does a vessel. The BLT specified Dyneema ropes may also be attached to a bollard in a way that creates a turning moment, similar to some of the forces experienced from a vessel. When used in conjunction with the BLT Directional Roller, the ropes can also be elevated to an angle of up to 20 degrees – thus simulating vessel spring lines and readily providing a great deal of confidence in both the bollard and its surrounding structure.

No, there are no reaction forces in the quay; it is a true test of a mooring line attached to a bollard.

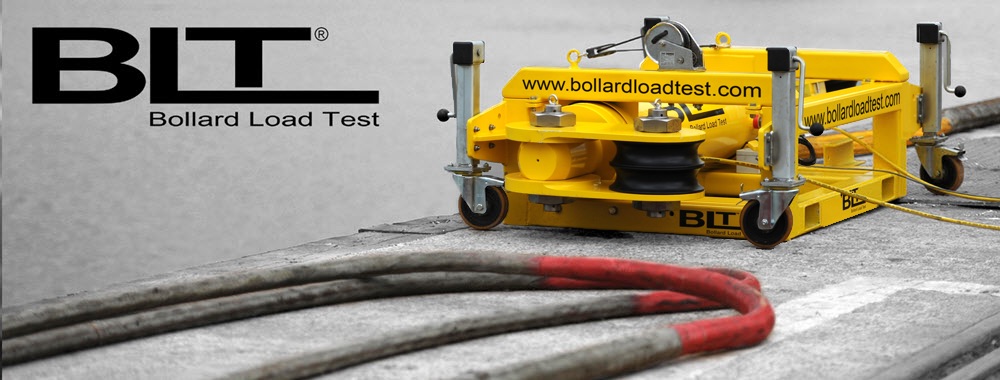

By using a powerful hydraulic cylinder, gradually increasing

pressure in four stages:

25 percent hold

50 percent hold

75 percent hold

100 percent hold

A drop in DNV-GL Witnessed Load Cell measures the load placed upon a bollard under test. Three remote cameras record the entire bollard load testing procedure, whilst lasers are targeted at the bollard to detect any microscopic movement.

Currently up to 120 tonnes. A 240 Tonne BLT System is in development.

When the bollard successfully holds a static Safe Working Load, or a specified Proof Load.

When the bollard does not hold a steady load at any stage of the test or; when the bollard moves, within its stated limits, and does not return to its original position.

The inspection and testing of mooring bollards in the UK falls under the requirements of the Provision and Use of Work Equipment Regulations 1998 (PUWER). BLT is compliant with the Unified Facilities Criteria (UFC) 4-150- 08 – Inspection of Mooring Hardware and operates to MIL-STD- 3007F.

A BLT Test Certificate is valid for twelve months, being the recommended minimum re-testing period. However; the tested bollard is certified for that load for that day, as BLT will not be held responsible for the future use of the bollard.

Approximately thirty minutes for a standard test.