Technical Data

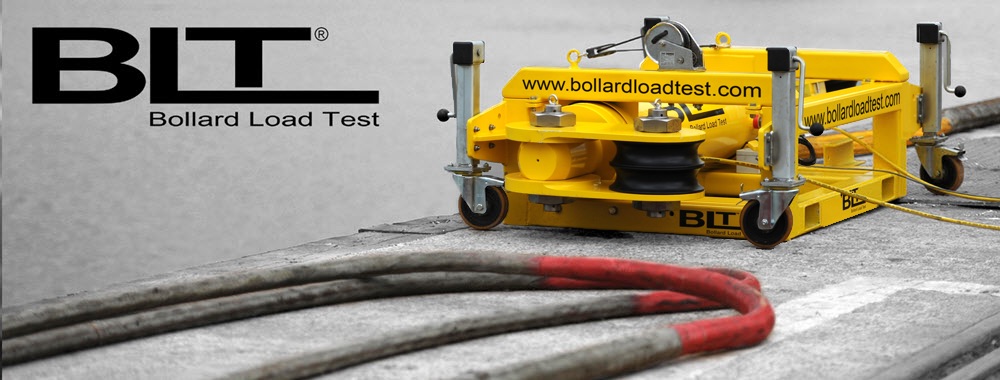

The BLT System is designed to safely test the strength of marine mooring bollards.

Bollards come in many shapes, sizes, capacities and materials and throughout their life will suffer corrosion, fatigue and other effects.

The forces exerted on a bollard are considerable, being in excess of 200 tonnes-force (metric), which can weaken the bollard and its fixings to the point that the bollard fails to withstand such forces. Should this happen, it can cause catastrophic damage to vessels, dockside equipment and to the quayside itself, as well as serious or even fatal incidents. It is therefore best practice to test mooring bollards at regular intervals, being compliant with the following regulations;

Mooring bollards fall under the requirements of the Provision and Use of Work Equipment Regulations 1998 (PUWER), of which Regulation 6 states;

“(1) Every employer shall ensure that, where the safety of work equipment depends on the installation conditions, it is inspected –

(a) after installation and before being put into service for the first time; or

(b) after assembly at a new site or in a new location, to ensure that it has been installed correctly and is safe to operate

(2) Every employer shall ensure that work equipment exposed to conditions causing deterioration which is liable to result in dangerous situations is

(a) at suitable intervals; and

(b) each time that exceptional circumstances which are liable to jeopardize the safety of work equipment have occurred, to ensure that health and safety conditions are maintained and that any deterioration can be detected and

(3) Every employer shall ensure that the result of an inspection made under this regulation is recorded and kept until the next inspection under this regulation is recorded.”

The breakthrough BLT technology uses a powerful hydraulic cylinder, DNV- GL Witnessed load cell and bespoke designed Dyneema ropes to recreate conditions that are equivalent to 120 metric tonnes of ‘pull’.

The BLT system allows for standardised testing of bollards by replicating the various forces and movements that they may experience when used to moor a vessel. The BLT system can simulate spring lines at various angles up to 20 degrees, thus giving a great deal of confidence in the bollards and their surrounding structures.

How safe are your bollards?

An often-overlooked area when it comes to the safe mooring of vessels in ports, shipyards and harbours is testing the safe working load (SWL) of bollards. With the ever increasing size of vessels, the time has come to focus and raise the issues that have been experienced with bollard failure, as well as the challenges faced in testing the SWL of bollards. To download the technical paper Click here